QA consists of establishing standards, guidelines and procedures to prevent quality issues and controls over the production and maintain the integrity of the product from development to end use. Our R&D team monitors the new product developments and conducts research to gather user requirements. They also play an active role in strategic planning by providing ongoing research-based input and advice.

With an in-house quality checking facility, the quality control department is leading the quality of raw, in-process and finished products in a superior manner. The department has the provision of testing and measuring various technical parameters as per customer requirements or specifications, and handling the quality issues is one of the major tasks, along with documentation of checking reports. Our quality team ensures that the perfect quality of packaging material is supplied to our customers to build trust and customer satisfaction.

The blown polyethylene film unit has a production capacity of 10000 MT per annum. We manufacture the best quality three-layer collation shrink film and poly films of a wide variety for lamination. Our W&H Optimex extruder provides excellent mechanical strength, and a completely automated machine provides precise operations. The thickness controller ensures easy downgauging and reduces micron variation with minimum wastage. This highly efficient machine hence promotes us to a greener future. Our Major suppliers for granules are HPL, IOCL, Dow Chemicals, and Borouge.

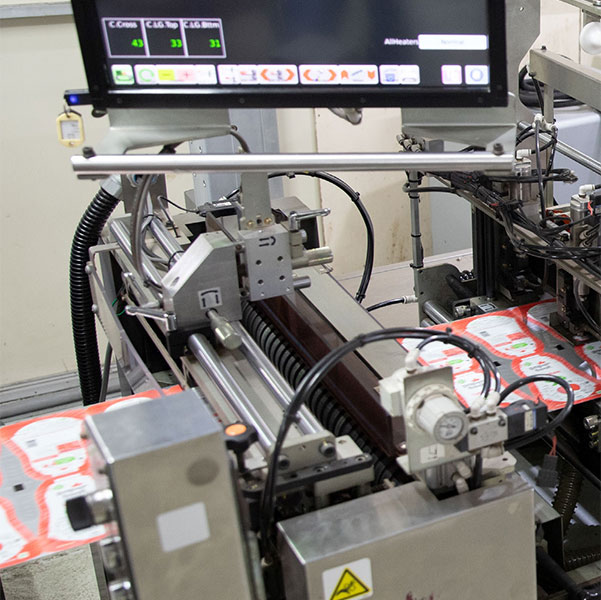

With the power of three high-speed rotogravure printing machines operating at an impressive speed of 500 MPM, our capabilities are unrivalled. These state-of-the-art machines, including the world-renowned WINDMÖLLER & HÖLSCHER, enable us to print up to 9 colours.

Its advanced drying system reduces energy consumption, making it a more sustainable option compared to other printing machines. It also minimises the wastage percentage. Its automated technology enables the calculation of tension as per the film type with a given Modulus of elasticity. With its exceptional capabilities, this state-of-the-art rotogravure printing machine elevates our manufacturing capabilities, enabling us to deliver high-quality and eco-friendly packaging solutions.

Our advanced turn bar facility, coupled with highly precise auto registration and auto viscosity control systems, guarantees impeccable print quality. Additionally, our expertise extends to a diverse range of materials, from polyester and PVC to PET-G, shrink film, BOPP film, foil, and paper, ensuring you bring your vision to life on any canvas.

We have three types of lamination processes:

We can laminate multilayer films with a speed of up to 375 MPM. To produce high-quality packaging materials, we have highly precise, fully automatic corona treatment facility machines like Nordmeccanica. It is a combi line in which simultaneously solvent less and base facility can be utilised. We laminate two or more films bonded together to achieve desired properties such as moisture and oxygen barrier protection, enhanced shelf life, heat seal ability, and printability.

We operate three state-of-the-art turret-type slitting machines to accurately cut master rolls into smaller rolls according to customer requirements. This process is a critical step in the finishing of mono web flexible packaging. Precise slitting is essential for preventing any sensor-related problems arising from uneven length variations. Our slitting capabilities cater to a wide range of customer needs, spanning from 200 BPM lines to 1000 BPM lines, particularly in the beverage industry.

Today's market demand for shrink sleeves is growing rapidly. Considering the temperature sensitivity of PVC and PETG Film, mostly used films for shrink sleeves, we have highly precise, fully automatic with both side auto turret system machines like Karlville. We have machinery with a speed of 500 MPM, which produces Seamless full-body shrink sleeves. Here, the major processes are seaming and rewinding. Rewinding is a complicated process, so we ensure proper rewinding is done by airfilling inside the shrink sleeves. That is how the defects are sorted, and the high-quality, flawless product is ensured to the market. It gives products maximum aesthetic impact and marketing exposure.

We manufacture Various types of pouches like three-side sealed pouches, central seal pouches, stand-up pouches, pillow pouches, spout pouches, shaped pouches and various customised pouches as per their requirements for top-quality pouches. We have fully automatic and innovative machinery made by Dalian Totani Corporation. We can produce 240 pouches per min.